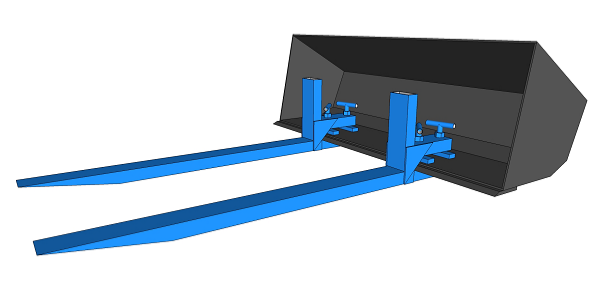

DIY Forks for your tractor and skid steer $10

Turn a tractor or skidsteer into an all terrain forklift.

Improved design and updated plans. Along with CAD and 3D drawings, it now also includes a material list, how to manual, and numerous diagrams to make construction simple. It is thorough and simple to follow.

Improved design and updated plans. Along with CAD and 3D drawings, it now also includes a material list, how to manual, and numerous diagrams to make construction simple. It is thorough and simple to follow.

Plan contents:

- Materials list

- Experience based how-to and many large illustrations and drawings. 20 size font so plans are easy to read.

- 2D CAD drawings of each part

- 3D Model Views in each CAD drawing to eliminate guess work

- Building tips

- Explanations on how to assemble the parts correctly

- Several assembly diagrams. Eliminates guess work

- You are shown where to weld, and how to keep parts from moving during welding

- How to attach to the bucket and safety precautions

- Prints can be printed on 8.5" x 11", or 11" x 17" paper.

- Designed for front end loader buckets with a 1/2" thick blade for most compact, subcompact tractors, SSL's, and CTL's, but can be readily scaled up for thicker blades.

- 90 day 100% money back guarantee. No hassles, no questions.

Why this design?

- Inexpensive

- Larger underside supports and clamping surfaces to prevent bucket damage

- Easy intallation and removal

- Two clamps for enhanced locking stability

- Will last as long as your machine. I've had mine for 10 years, and there is no wear or damage on them, and I use them a lot.

- 2000 Lbs evenly distributed median load per fork (1600 Lbs with 1.5x safety factor) / 4000 Lbs per pair (3200 Lbs with 1.5x safety factor)

- Heavy Duty

- Built with common tools

- Only a few beads of weld required

- Built with common materials

- Good weekend project

Minimal parts needed: 10 parts per fork need to be made, mostly straight saw cuts. 15 parts in total. 11 through 15 are purchased (Nuts, bolts, etc.)

The forks are designed to be built with common tools, so you don't have to own a fabrication or machine shop to build them. These forks are not beyond the skill set of the average DIY craftsman using common tools.

The forks are designed to be built with common tools, so you don't have to own a fabrication or machine shop to build them. These forks are not beyond the skill set of the average DIY craftsman using common tools.

90 day money back guarantee. If for any reason you are not satisfied with these plans, let me know, and I will refund your money. No questions, no hassles.

"Hi Brad,

I downloaded your fork plans yesterday. Great plans! I am newly retired and this is going to be my first metal works project."

Regards,

Matt S. ~ from Whiteplains, NY

I downloaded your fork plans yesterday. Great plans! I am newly retired and this is going to be my first metal works project."

Regards,

Matt S. ~ from Whiteplains, NY

Buy at least two sets of plans and get 25% OFF your entire order. Enter discount code "2020springsale" at checkout. Limited time offer.

Arnold's Design © Copyright 2010 - 2020

All Rights Reserved

All Rights Reserved