Vapor Blasting Services

What is Vapor Blasting?

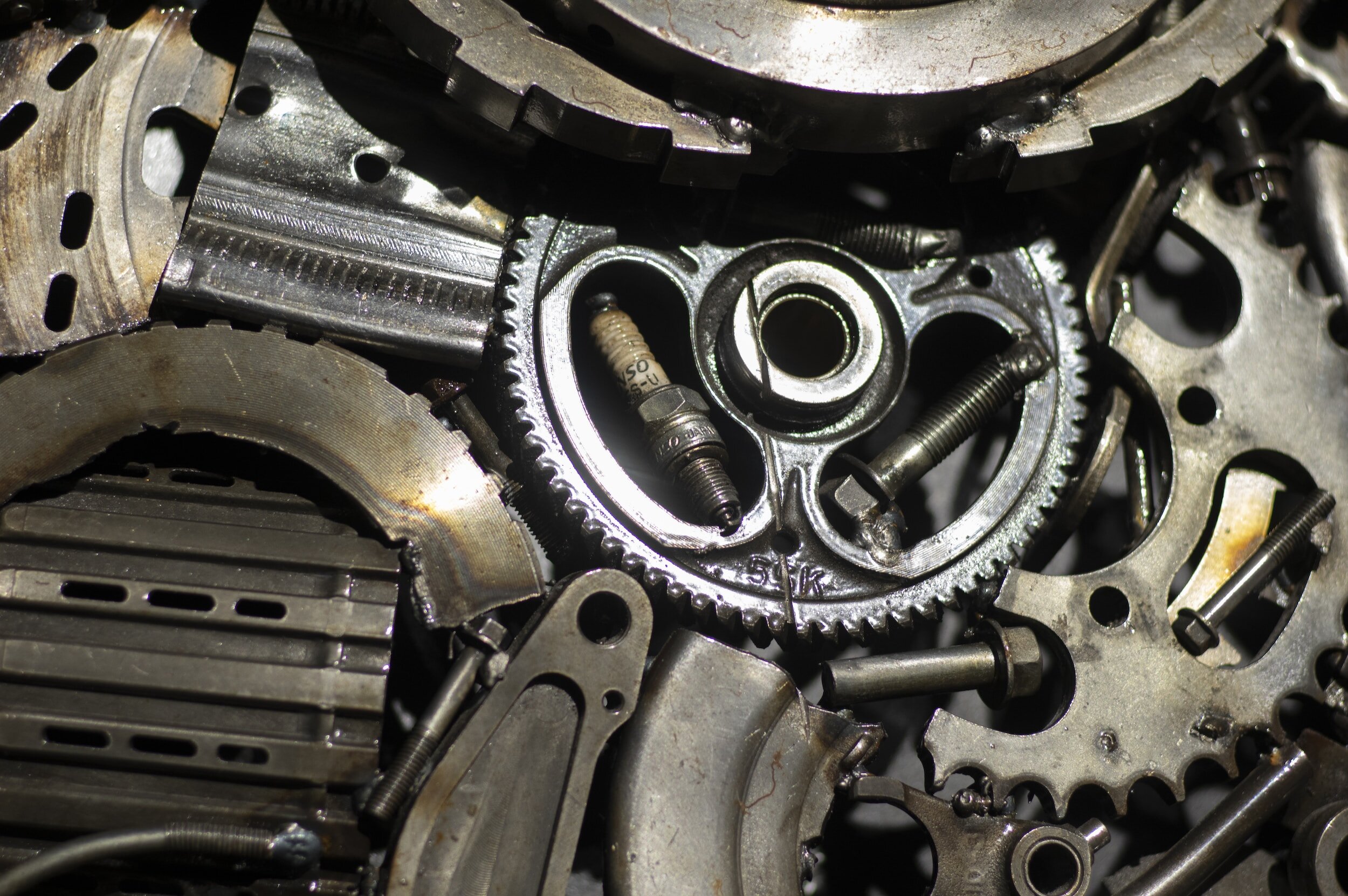

Vapor blasting, also referred to as wet blasting, has gained significant popularity as a highly effective method for preparing and cleaning surfaces. This specialized form of abrasive blasting harnesses the power of water, which is combined with an abrasive media like glass beads, aluminum oxide, or crushed glass.

By utilizing this unique mixture, vapor blasting not only removes dirt, rust, and other undesirable particles but also leaves the surface immaculately prepped for further treatments or coatings. Its inherent versatility and ability to optimize adhesion make vapor blasting an indispensable tool across various industries, ranging from automotive and aerospace to metal fabrication and restoration.

Why Arnold’s Design?

Arnold’s Design has been offering vapor blasting services since 2010. Over that time, we’ve restored thousands of parts and honed our skills to be one of the best in the business.

When Arnold’s Design opened in 2010, there were only a handful of shops across the United States doing vapor blasting work. This gave us the opportunity to finesse our craft by working on TONS of different parts for all kinds of vehicles. As vapor blasting popularity grew, quite a few shops have opened across the country but few have our experience or knowledge. We often receive part from customer who’ve taken their parts to other vapor blasting shops with less experience, only to send the parts to us to re-do properly.

Don’t spend your time and money on someone who “might” get it done- Arnold’s Design has the know-how to get the job done right the FIRST time. Contact us today for a quote at b.arnold@arnoldsdesign.com!

Vapor Blasting Services: What It Is and Is Not

Water, micro beads, mild cleaning agents, and air are mixed into a slurry and propelled at high speed toward the surface of a metal part, such as aluminum, brass, as well as mild steel. It seals the surface, resulting in cosmetic enhancement and imparts a micro finish that helps it resist further staining and oxidation.

The water component of the slurry provides a hydraulic cushioning effect to soften the microbead's impact on the metal's surface. Working together, they provide a gentle, and somewhat time consuming process that peens the metal surface and leaves a bright lustrous satin finish. Finishes vary from alloy to alloy with aluminum castings in particular being well suited to this.

Developed during the second world war, vapor blasting was initially used in industrial settings to create surface tension in parts to strengthen them. Rolls Royce used it to strengthen turbine blades before assembly into jet engines. The British spelling is vapor blasting, and it is quite popular there for bike restoration.

Vapor blasting is like metal polishing, anodizing, or plating, in that it is a finishing process. Due to the nature of the process, cleaning does occur, but that is not the objective of vapor blasting. Just as with other finishing processes, preparation is key to a quality vapor blasted finish.

Though vapor blasting is not a cleaning process, Arnold’s Design does offer cleaning and hot tanking. The removal of carbon and dried dirt is included in the cost of vapor blasting. We can also remove greasy dirt, oil, baked on oil, grime, gaskets, paint, silicone, and 2 stroke case sealant. Additional per hour charges apply for cleaning.

Deoxidizing, and Vapor Blasting at Arnold's Design

This video shows what is involved in vapor blasting a a Stainless Ducati Exhaust. This process can be used on motorcycle parts as well as automotive parts. Vapor blasting is a metal finishing technique that works best on non ferrous metals, such as aluminum, and brass.

Interested in Vapor Blasting Services for your parts?

Contact us about your project, and we’ll help breathe life back into your old parts!